A time honored way to strengthen materials is internal fiber reinforcement or ¨straw in bricks¨.

But reinforcement is difficult because HTS is made by first melting component powders at ≈ 1200°C, then cooling under oxygen. Reinforcing material placed inside oxidizes at high temperatures, forming impurities which interupt crystal growth and form secondary seeding sites. These weaken HTS crystal strength and hurt performance. HTS strenghtening has so far been limited to external reinforcement such as Packing in Tubes, Deposition on Substrates, or Stainless Steel Encasing.

A Solution

REINFORCE HTS WITH LONG CONTINUOUS SILICON CARBIDE (SiC) FIBER

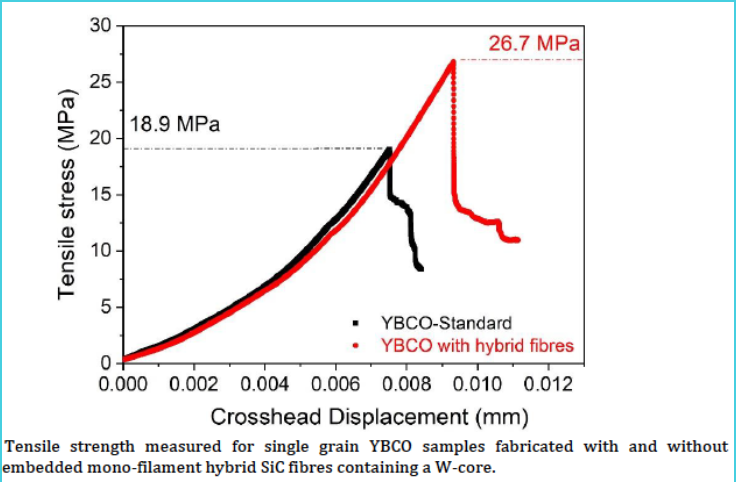

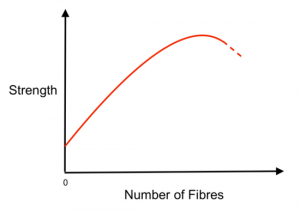

RESULT: 40% gain in strengh with just three 100 μm thick SiC fibers in a 25mm diameter sample.

Silicon in SiC fibers reacts at high temperatures with O2 creating a layer of inert SiO2 preventing further oxidation. This is similar to how chromium (Cr) makes steel stainless.

1. Reinforced High Temperature Superconductors

1.1 Confirmation of Fiber Pacification and Strength Enhancement

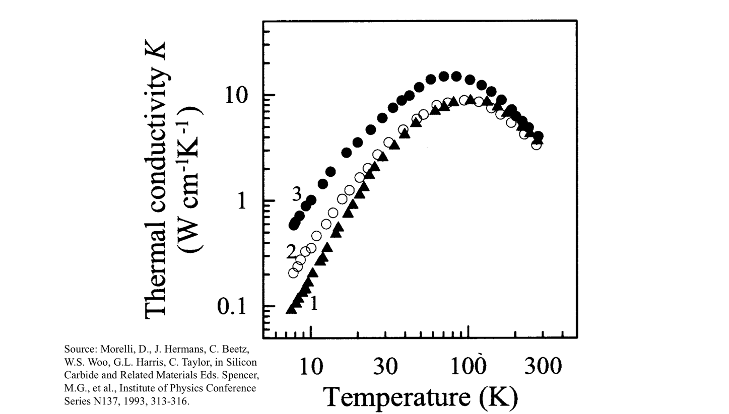

1.2 Heat Conduction

We are exploring using the ability of reinforcement fiber to drain heat internally from a superconductor. SiC has excellent heat conductivity at HTS operating temperatures. Because excess heat is a fundamental cause of superconductor failure, draining superconductor heat internally would improve superconductor performance.

1.3 Microscopy

We are examining the microstructure of fiber reinforced HTS to confirm passivation; a key observation would be the thickness of any passivation since this will affect maximum fiber density.1.4 Flux Pinning

We are exploring whether internal fiber improves HTS flux pinning.1.5 Markets

- Replacing existing non-reinforced HTS in markets for magnetic bearings. We work with CAN Superconductors, one of the world’s oldest and largest commercial HTS bearing makers.

- Replacing HTS tapes and wires in Superconducting Fault Current Limiters. Reinforced bulk HTS offers higher capacities and better SFCL performance at lower cost.

- New Application: Superconductor Actuators replacing aircraft hydraulics.