A time-honored way to strengthen materials is through internal fiber reinforcement or ¨straw in bricks¨.

But reinforcement is difficult because HTS is made by first melting component powders at ≈ 1200°C, then cooling them under oxygen. Reinforcing material placed inside oxidizes at high temperatures, forming impurities which interrupt crystal growth and form secondary seeding sites. These weaken HTS crystal strength and hurt performance. HTS strengthening has so far been limited to external reinforcement such as Packing in Tubes, Deposition on Substrate, or Stainless Steel Encasing.

A Solution: REINFORCE HTS WITH LONG CONTINUOUS SILICON CARBIDE (SiC) FIBER

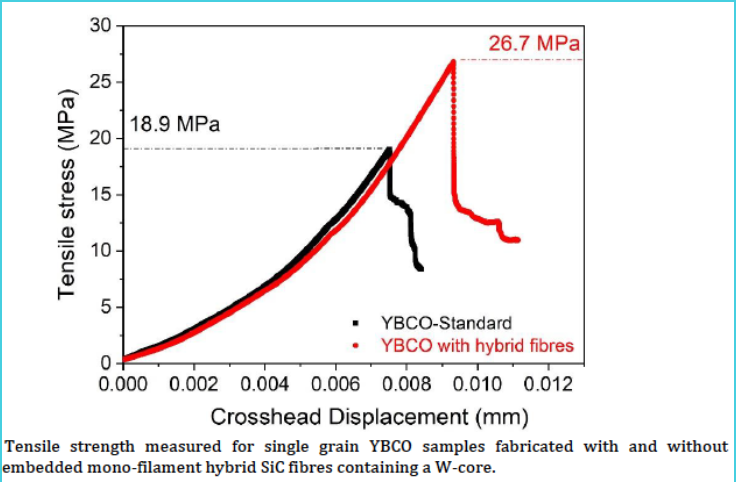

RESULT: 40% gain in strengh with just three 100 μm thick SiC fibers in a 25mm diameter sample.

Silicon in SiC fibers reacts at high temperatures with O2 creating a layer of inert SiO2 preventing further oxidation. This is similar to how chromium (Cr) makes stainless steel.